According to the Federal Motor Carrier Safety Administration (FMCSA), large single-unit and combination trucks travel hundreds of billions of miles each year, transporting countless shipments to stores, warehouses and customers across the country. However, none of this activity is possible without an operable truck. Routine maintenance, as standard as it may seem, can play an important part in keeping your business running profitably.

Preventive truck maintenance programs

The following insights detail some of the benefits routine truck maintenance can provide and what fleet managers can do to prioritize vehicle health year-round:

Reduced breakdowns

Preventive maintenance can reduce equipment failure, resulting in better equipment uptime and, in turn, better customer satisfaction.

Reduced maintenance

Properly scheduled maintenance inspections provide opportunities to make minor repairs and adjustments that can help prevent premature wear and identify mechanical failures before they become catastrophic.

CSA scores and public perception

CSA program/SMS scores are critical in fostering a public perception that your company offers reliable transportation services. Maintenance can help keep your equipment clean and ready for CSA inspections.

Documenting commercial truck maintenance programs

Each fleet’s commercial truck maintenance program will vary based on factors like size of fleet, staffing and type of vehicles in the fleet. No matter the size of your fleet, documenting your maintenance program can help provide clarity and informed direction to your employees. By formalizing a maintenance program, you can detail expectations for maintenance performed; who is responsible for each task; what documentation needs to be completed; how long that documentation needs to be maintained and where it should be saved.

Documenting these requirements can save you time and money in the long run. By keeping clear records, you may be able to identify cost-efficiency opportunities, determine if certain vehicles are more costly than others and analyze trends related to drivers or truck maintenance personnel that would not be possible without that data being collected. It also sets expectations for everyone in the organization to do their part to maintain equipment and meet DOT regulations.

The importance of detailing a maintenance schedule

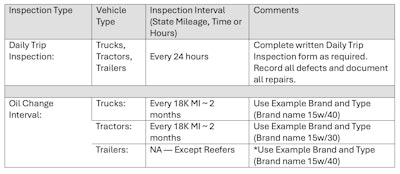

One important feature of a maintenance program is the periodic maintenance schedule. On this schedule, you can include as much detail as needed. Some elements to include in your schedule include-

Inspection type

This should listall your regular maintenance tasks, such as daily trip inspections, greasing intervals, visual inspections, oil change intervals, manufacturer schedules and annual inspections.

Vehicle type

If you perform different maintenance tasks on trucks, tractors, or trailers, detail those differences on your maintenance schedule.

Inspection intervals

Inspection intervals can include different metrics. For example, certain tasks may only be necessary every two months or 40,000 miles. Comparatively, other tasks may come due every 12 months regardless of vehicle use. Be sure to specify the intervals at which each task should be performed.

Comments and additional considerations

Detail expectations for forms that need to be filled out, brands to use in each vehicle, weights for oil, specifications for your preferred parts, etc. This can fill in all the remaining details not clearly outlined in other categories.

An example format for truck maintenance schedules is included below.

Setting up your schedule to include the full list of inspections you perform can help you keep track of all the tasks that need to be completed. It also provides a simple visual for record keeping so if anyone needs to audit your records, it is clear what maintenance has been completed.

Detailing each of your truck maintenance tasks in a schedule can set clear and informative expectations for what needs to be done and how to document it appropriately.

Driver vehicle inspection reports

Pre- and post-trip vehicle inspections, which are required by the FMCSA, can yield valuable feedback that helps you prevent catastrophic breakdowns before they occur. Providing a useful, understandable, repeatable tool for drivers to fill out can instill confidence that their concerns will be heard. These inspections also produce the documentation and information you need to get ahead of maintenance needs.

Consider using electronic logs and maintenance reports. These digital records are harder to lose and can be immediately transmitted to both management and truck maintenance teams. Whether you’re using paper or electronic forms, ensure your drivers understand how to complete the inspections and what to do if they recognize issues.

Routine maintenance may seem tedious, and documentation may sound even less appealing, but both practices can have a profound impact on a trucking fleet’s bottom line. Failing to proactively address issues through maintenance can lead to expensive repairs. Failing to document maintenance tasks can lead to unnecessary headaches and increased scrutiny if things go wrong. Keeping up with maintenance can help keep you rolling profitably.

Cliff Johnson is a Trucking Segment Business Consultant at Acuity Insurance. Cliff began his career in the trucking industry operating intrastate before expanding his operations into 48 states and Canada. Over time, his experience provided him opportunities to work in several industries transporting a variety of cargo utilizing specialized trailer configurations. Through his trucking business, Cliff continued hauling commodities serving the forest and paper industries, as well as aggregate, fuels and heavy haul.